Please refer comparison chart.

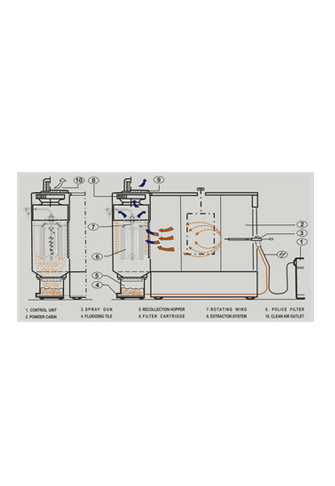

Cartridge Recovery Powder Spray Booth

Get the highest power recovery and fast colour change with cartridge recovery powder spray booth

Get the highest power recovery and fastest colour change with a cartridge recovery system. 99.99% of the powder sprayed is recovered. Get more coating per kilogram of powder used.

Oxy-Cartridge Recovery Booth

Summary of Benefits:

- 99.99% power recovery

- No need to mix new and old powder. All over sprayed powder can be used. More coating per kilogram of powder

- Lower power consumption as no after filter is required

- Horizontal flow assures uniform film thickness

- Higher life of cartridge filter with unique Rotary wing cleaning mechanism

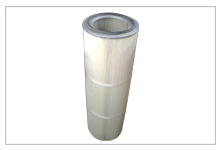

Cartridge

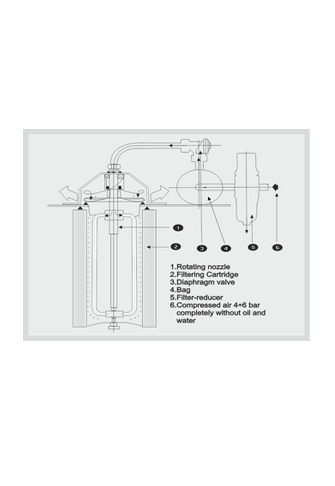

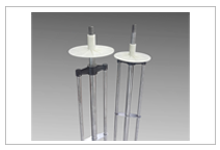

Cartridge  Rotating Wing Mechanism

Rotating Wing Mechanism Working of Rotating Wing Mechanism

Working of Rotating Wing MechanismFrequently Asked Questions

The high efficiency fan sucks the air and overspray powder through spray booth towards the cartridge filters. The powder is blocked by the cartridge filters and only clean air is released into the atmosphere.

Powder deposited on the outer surface of the filter will be dislodged by the high pressure air which is purged by Mitsuba’s unique Rotating Wing Cleaning Mechanism.

Rotating Wing Cleaning Mechanism rotates inside the cartridge filter at very high speed for the set time. While rotating inside the cartridge it also purges the air at pressure inside the cartridge. The purged air is introduced across the height of the cartridge. The purged air will dislodge the powder which is deposited on outer surface of the cartridge filter.

Conventionally, cartridge filters are cleaned by reverse pulse jet system. Reverse pulse jet system releases a high pressure jet of air inside the cartridge. The shock generated by the air blast dislodges the powder deposited on the outer surface of the cartridge. The shock of air in this cleaning mechanism never reaches the bottom section of the cartridge filters. The powder will accumulate on the cartridge and will result in higher pressure drop and powder will escape out of the booth into the atmosphere. While rotating wing cleaning mechanism will purge the air uniformly throughout the height of the cartridge and will keep the cartridge clean all the time. With Rotating Wing Cleaning Mechanism no powder will escape out in the atmosphere.

The old powder is mixed with new powder to achieve the desired powder particle size distribution. In the cyclone recovery, powder particle size changes after every cycle. To maintain the desired particle size distribution new and old powder is mixed. The cartridge recovery does not change the particle size distribution in recovered powder over fresh powder. Recovered powder can be used as it is for consistent quality coating.

No, it is not recommended. There is a very high possibility that it will contaminate the powder. The standard practice is to keep dedicated cartridge filters for each colour.

Yes, we can.

We need sizes of the products to be coated, conveyor speed, entry-exit cut out of the booth and the number of colours you will operate.

ENQUIRE NOW

Manual Powder Coating Equipment

Sprayright

Tribo Series - Manual

Portable Powder Coating Equipment

Automatic Powder Coating Equipment

Automatic Powder Coating Gun Movers

Powder Coating Booth & Recovery

- Powder Coating Booth with Cyclone Recovery - UNI Series

- Powder Coating Booth with Rotary Cyclone Recovery - CAT Series

- Powder Coating Booth with Cartridge Recovery - OXYGEN Series

- After Filter Suitable For Cyclone & Rotary Cyclone Recoveries

Sievers

Special Powder Coating Equipment

- PTFE- ECTFE Powder Coating Gun

- Pipe Coating Equipment

- Rebar Coating Equipment

- Compact Gun & Booth for Powder & Resin Manufacturers

- Fast Colour Change Gun For Powder & Resin Manufacturers

- Powder Coating Equipment For Fluorescent Penetrant Inspection Process

- Powder Coating Machine to spray Boron Nitride powder for aluminum extrusion application

- Talc Powder Spray System For Green Rubber Tubes

Attachments

X